Delivery programme

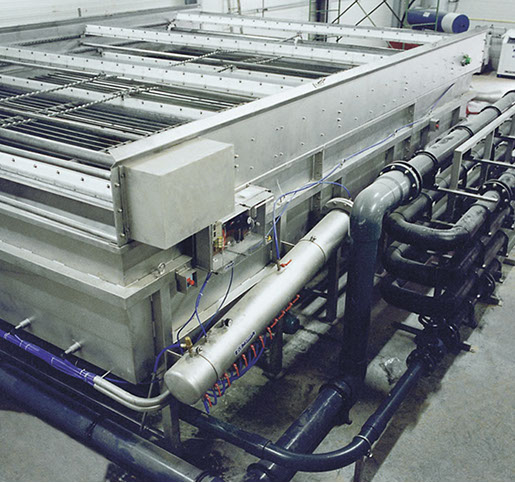

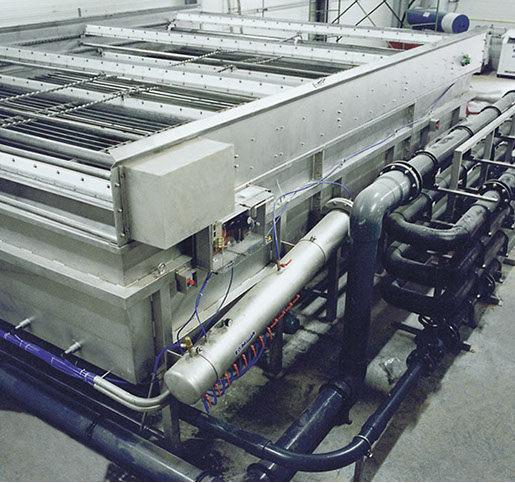

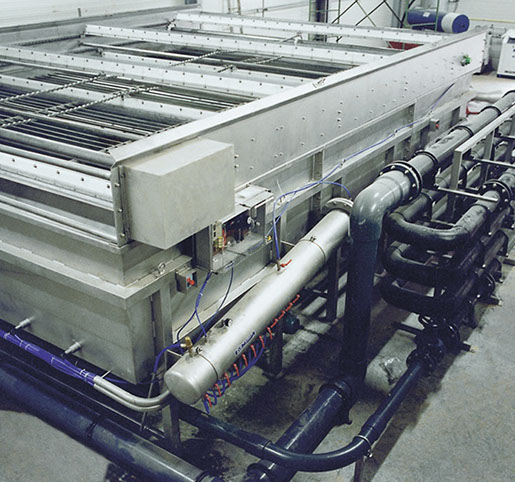

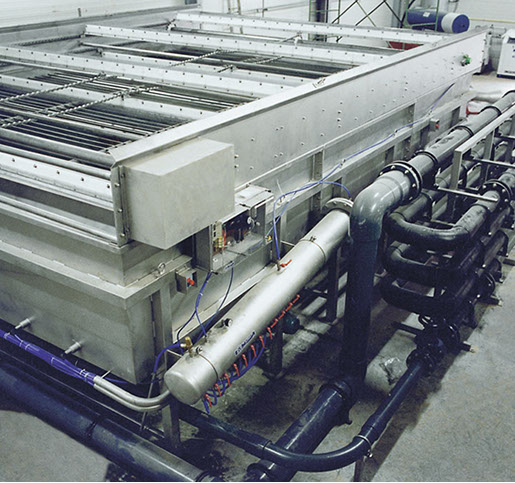

Dissolved air flotation PFL

Operating principle

The dissolved air flotation is a separation method in which pressurised air is dissolved in water and the smallest air bubbles are created when the pressure is reduced (release), which accumulate on floating solid particles as they ascend, thus enabling their flotation. During Planotex dissolved air flotation, a partial current of clear water is generally saturated with air at an excess pressure of 4-6 bar and then conveyed into the flotation tank via the release valves on the inlet side of the wastewater. After release of the atmospheric pressure, the excess air escapes in the form of fine bubbles. The gas bubbles form a agglomerate in the contact and mixing zone with the solids, which due to its low density rises to the surface of the tank and can be cleared away there.

The PFL model flotation is used for heavily polluted wastewater that produces corresponding amounts of flotation sludge, and therefore has a larger tank surface for adding the amount of flotation sludge.

Features

• Standard system of 5 to 180 m3/h capacity

• Stainless steel container

• Efficient recirculation system and micro-bubble generation

• With sediment outlet

• Application with many industrial wastewaters for separating fats, oils, and dissolved pollutants, floating and suspended matter, and settling sediments

• Highly suitable for separating excess sludge from biological wastewater treatment

back